Project info:

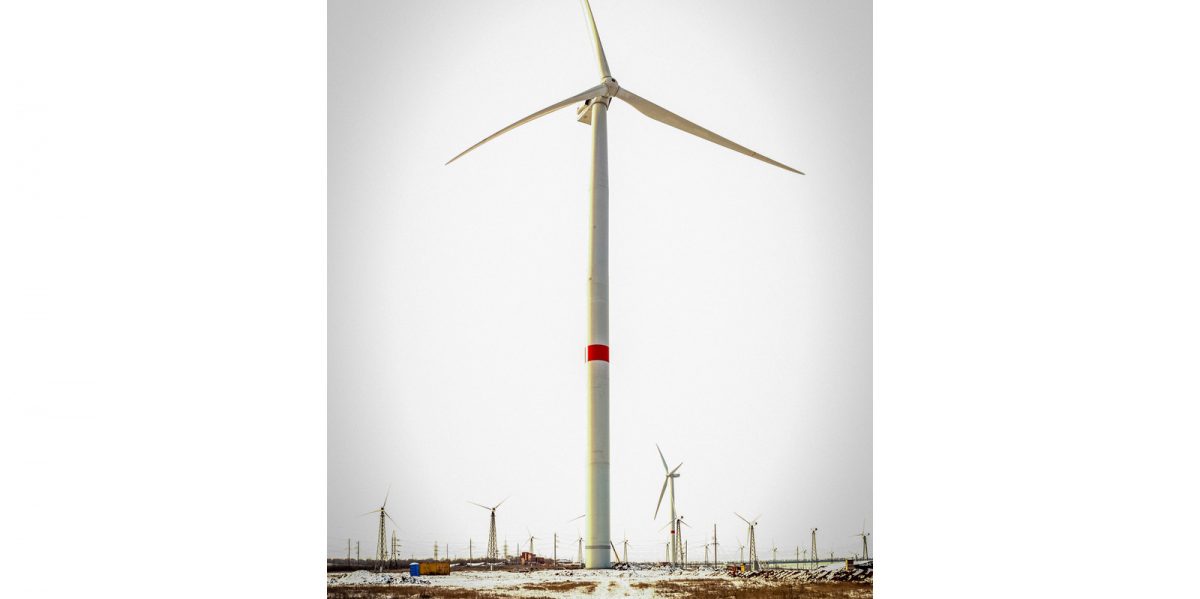

Logistics and assembly of wind power generating plants.

Client

Categories

Location

Year Completed:

ОПИСАНИЕ ПРОЕКТА

Geodetic and cartographic services

Horizontal — vertical geodetic 8 points network was created for the purpose to provide further designing and mapping work.Land surveying of the area at about

64 hectares (1:1000 scale) and 94 hectares (1:500 scale) created basis for digital vector planning of area. On this basis Designing Institute designed places for mounting of 23 wind turbines, as well as track roads and cable lines.The objects were positioned by dual-frequency GPS-receivers «TRIMBLE» R7 and R8 under the World Coordinate System WGS-84 and under the Government System SC-63, up to 1 cm precision.Planned mounting positioning of anchor bolts was checked by tacheometers «TOPCON» GPT-7501 and «SOKKIA» SET 330 R.Altitudinal position of anchor installation was checked by digital leveling device «Leica»DNA 03. With anchoring diameter 4 m maximum allowable error could be 3 mm in plane and 1 mm in height.Upon additional requirements of the company «Führländer» it was created digital vector map with a scale of 1:10 000, detecting all present, being designed and going to be built WDPP, located at «Novoazovsk wind farm»

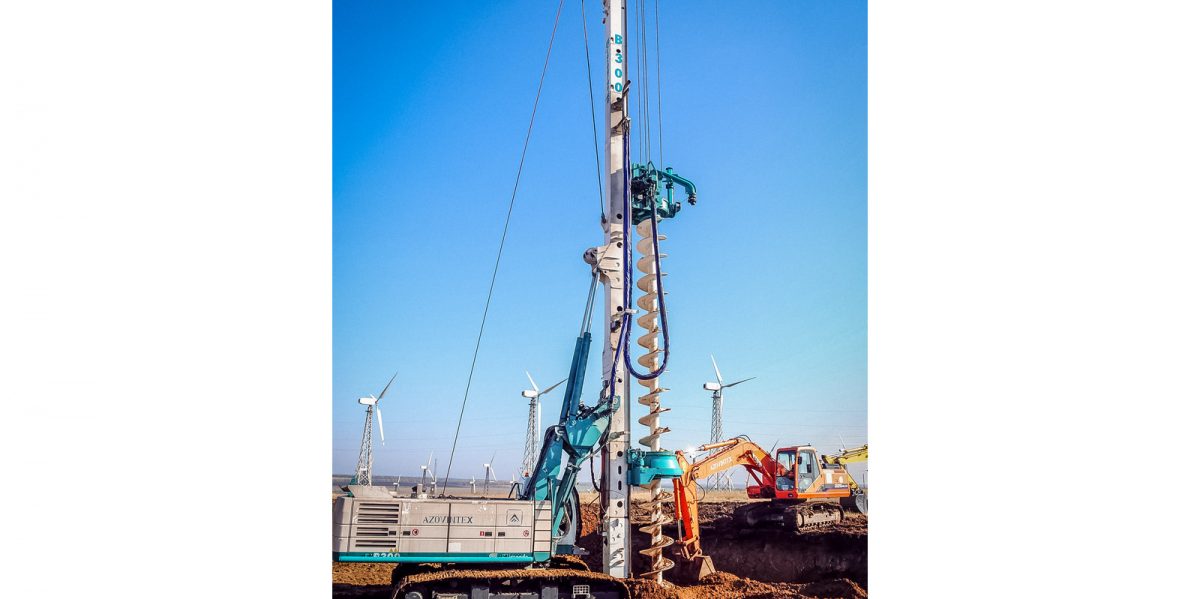

Excavation and drilling works

During the operation, WDPP undergo significant horizontal and vertical loads transferred to the foundation.

For this reason, the foundations demand the most rigid requirements for durability and reliability. To meet these requirements, the project supposed the construction of GKN driven piles.Performance of these works was one of the most important stages of the project.After topographic measurement and final determination of exact positioning of wind turbines there was made a barrow pit for each foundation (mechanics: excavators JCB-225, Daewoo Solar 220).Filling the holes with a concrete mixture after cages insertion was carried out by stationary concrete pumps Wazinger.Concrete with cement brand M 600 was manufactured at enterprise’s Industrial Construction Complex, excavation and drilling works were managed by Direction for Industrial Construction of PBE «Azovintex» Ltd.

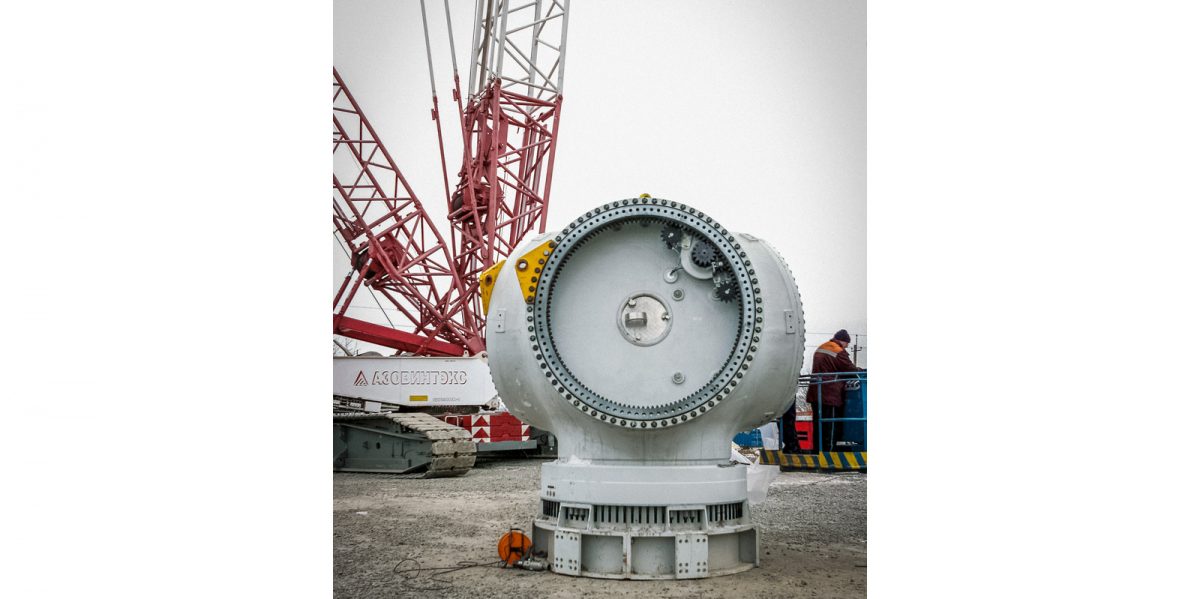

Foundation works

Foundations for wind turbines were designed according to the manufacturer’s equipment with the characteristics of the soils. The shape of each foundation is a complicated thing, the lower part of which — the cylinder, the top — a truncated cone. Diameter base – 18 meters, height — 3 meters, volume – 556 m³. The base with total weight over 1000 t is intended to ensure stability and reliability of a hundred-meter giant.After pile works had been finished, builders began the preparation of concrete — filling a monolithic plate with diameter of 18 meters and thickness of 260 mm, on which armature cage should be set.

Special built-in items belong to concrete preparation for the installation and alignment of anchor device. A distinctive feature of foundations for wind turbines — the extremely high content of the steel reinforcement. Step reinforcement in the frame does not exceed 100 mm, which requires the usage of vibrators for packing concrete.Concreting of foundations was carried out simultaneously by two concrete pumps. Concrete truck mixer Volvo were used for concrete supply (load — 8 m³).Concrete care activities were provided after completion of concreting, with constant monitoring of temperature and strength.Damp course activities were carried out after completion of mentioned activities.In consequence of careful preparation, the availability of modern tehnology and high staff level, installation of foundations was performed in the shortest time and at the highest level of quality.

Special built-in items belong to concrete preparation for the installation and alignment of anchor device. A distinctive feature of foundations for wind turbines — the extremely high content of the steel reinforcement. Step reinforcement in the frame does not exceed 100 mm, which requires the usage of vibrators for packing concrete.Concreting of foundations was carried out simultaneously by two concrete pumps. Concrete truck mixer Volvo were used for concrete supply (load — 8 m³).Concrete care activities were provided after completion of concreting, with constant monitoring of temperature and strength.Damp course activities were carried out after completion of mentioned activities.In consequence of careful preparation, the availability of modern tehnology and high staff level, installation of foundations was performed in the shortest time and at the highest level of quality.

Transport services

The general success of the project depends upon the establishment of transport to ensure each of its stages.Timely delivery of individual parts to the job site, as well as of the used mechanisms and tools, contributes to the coherence and compliance with the scheduled dates.Capabilities of vehicle park of PBE «Azovintex» Ltd allowed to satisfy fully all needs appeared during mounting works Equipment, used for delivery to the job site:

Truck tractors VOLVO FH 12, VOLVO

FH 1916, MERCEDES-BENZ ACTROS 4154;

Trailers: NOOTEBOOM EURO 124-35 (Payload 89 t), COMETTO XA3DAP (Payload 48 t), FAYMONVILLE VARIO Z2.

Logistics of the project stipulated two phases of wind turbine parts delivery to the job site:

1 stage – Delivery of equipment from the port Mariupol to the temporary storage area, where preassembly was made, if necessary.

2 stage – delivery of wind turbine parts from the temporary storage area directly to the job site.

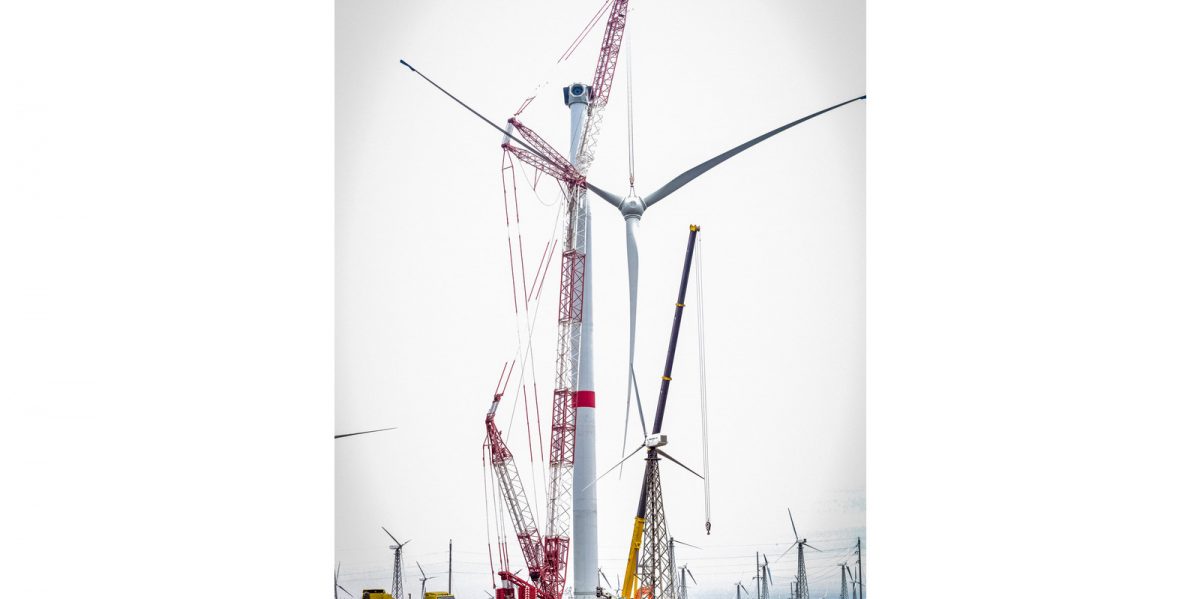

Installation of wind turbine

In view of the fact of height of WDPP and considerable weight of its individual parts, it was decided to use as the main lifting equipment a crawler crane Terex Demag CC 2800 with weight capacity of 600 tons and boom length 132 meters. The total weight of the assembled crane reached 500 tons.It was prepared a platform 30*40 m for installation and safe operation of the crane. The surface of this area according to the technological requirements should be almost horizontal (sloping surface not more than 0,3º) and stand necessary pressure. To do this, after planning, the soil was double dumped with a seal vibratory roller.Tower sector was turned over after delivery to the job site (into upright position) with the help of two cranes: Terex Demag and Grove, as well as with special rigging devices.Crane Terex Demag lifted sections one by one and they were connected to each other with steel bolts. Joint places were treated with sealant.Communication between installers and crane operators was supported per radio.Nacelle was delivered to the jobsite fully assembled. The total weight of the nacelle is 96 t.A super-lift device was used to lift the nacelle up to the designed position.During this operation the counter weight of crane amounted 90 t.Due to the large dimensions of rotor, assembled with blades, they were delivered to the job site in parts (components of the rotor blades).

Lift was preceded by several preparatory steps:

- Setting the support stand for the assembly of the rotor.

- Assembly of the hub enclosure.

- Alternate connection of blades with the rotor (the operation was carried out with the help of two cranes).

Before lifting, assembled unit with weight of 68 t with the help of two cranes was moved in a vertical position. Then lift up to the junction point.The tower consists of 6 different parts with different height and weight (from 27 to 67 t), connected together with steel bolts. Five sections are cylindrical shaped, upper section – truncated cone shaped.Diameter of the tower (five sections) – 4300mm, the upper part – the transition from 4300 to 3200mm.

The total height of the tower – 95 meters.

The total weight of the tower – 298,6 tons.

The final stage of the foundations works – waterproofing. In order to protect from the effect of moisture “body” of the basement is covered with special tar.Before lifting, each tower section is removed from the truck and trailer and with the help of two cranes is moved to a vertical position. After this operation, it is lifted up and installed to designed position. (height – 15-22 m, weight – 56-61 t).

SCOPE OF THE PERFORMED WORKS

Installation of pile bases (m3)

Reinforced concrete foundations (m3)

Armature (m3)

Construction of roads (m2)

Site arrangement (m2)

Repair of roads (m2)

Installation of equipment (tons)

Laying of cable lines 35 kV (km)

Feasibility study of imported goods (tons)