QUALITY MANAGEMENT SYSTEM

Since 2007 Quality Management System has been developed in accordance with requirements of international standard ISO 9001 and is effectively in operation and tested in practice at the enterprise. First certification of quality management system of the enterprise was done at the beginning of 2008 according to version of the standard ISO 9001:2000.

In 2009 and 2012 certification audits of quality management system of the enterprise were carried out by authorized certification body TÜV Thüringen e.V. Germany according to version of the standard ISO 9001:2008. Yearly performed external audits (by the third party – TÜV Thüringen e.V) confirm system development and improvement.

Quality system extends to following fields:

- – general contracting activities and elaboration of design documentation;

- – realization of construction projects of industrial and civil construction.

- – transport services;

- – production and sale of construction materials including nonmetallic materials.

Quality system covers the whole complex of installation and construction works at the enterprise including:

- -general contracting activities and design;

- – supply of completing parts, equipment, materials;

- – production, installation, inspection, test of all units, equipment and materials;

- – construction, startup and adjustment, object handover to commissioning;

- – services from contractors, subcontractors and suppliers.

While realization of large investment project, Quality insurance plans (of the project) are in general elaborated according to requirements of the standard ISO 10005:2005 with appointment of project manager and additional responsibility of executors and it enables to realize projects good and in due time. Quality system is based on skilled personnel of architects, designers, highly qualified specialists of the enterprise, workers having both deep knowledge and solid production experience in filed of construction.

In order to achieve best results while construction the enterprise uses advanced technologies, modern high production equipments, machines and machineries, control and geodetic apparatus of world’s leading manufacturers, high-performance construction materials. Key aspect of quality insurance of installation and construction works is manufacturing quality of steel structures both at subsuppliers and while erection.

Quality System for Welding Production has been developed in accordance with requirements of international standard ISO 3834-2 and it is effectively in operation and passed through certification at the enterprise in 2010.

Certification has been carried out by national certification body “PATONCERT”. Supervisor for welding works, welding technology and welders have been certified to the requirements of international and national standards.

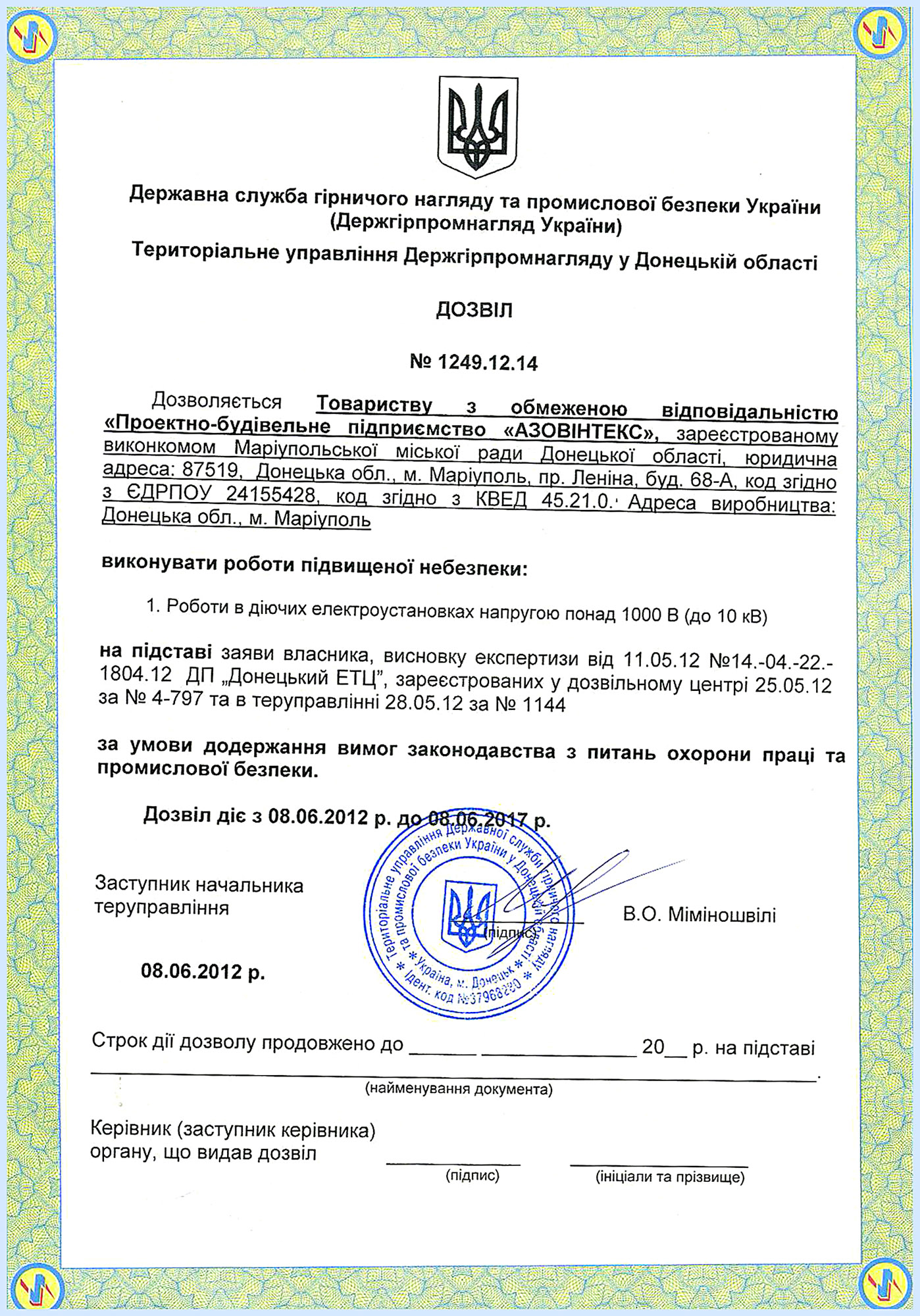

With the purpose of independent control (as the second part) of quality of weld joints and materials “Nondestructive Testing Laboratory” was organized at the enterprise and certified by Gosgorpromnadsor of Ukraine and this laboratory has Competence Certificate and Work Permit Certificate.

Besides there are “Central testing Laboratory” for quality control of construction materials and “Electrotechnical Laboratory” which have been attested by Bodies of Gospotrebstandard of Ukraine. All this enables to perform works for the Client good and in due time.

Quality certificates:

are available for construction materials, structures, items, used in construction.

Used quality control means:

- – instruments of concrete (mixes) test laboratory;

- – instruments of laboratory for nondestructive control methods of weld joints with radiographic, ultrasonic, capillary and visual optic methods;

- – instruments of electrotechnical laboratory for measurement of time and frequency and electric and magnetic measurements and tests;

- – geodetic instruments.

High quality and accuracy of transit and stadia method are provided with usage of electronic tachometer, laser measuring tapes and filed computers in work. Building and Projecting and building enterprise “Azovintex” has special high-sensitivity equipment which helps to search and detect underground utility lines of various applications and determines depth of their occurrence.

Topographic location plan is created on the basis of results of topographic survey. Complex of special activities – project setting-out is carried out in order to transfer ready project from media to location.

Occupational Health and Safety:

The enterprise prioritizes matters of creation of safety and non-hazardous conditions of work for employers, safety improvement, workplace hygiene and providence of employers with safe workwears, safe shoes and other individual protective means.

In connection with extension of vehicle park standing operating program for staff run up and professional training is realized by the enterprise.